deneme bonusu veren siteler

deneme bonusu veren siteler

bahis siteleri

Architectural & Ballast Rubber Roof Pavers

Please note: all of our photographs are in its original context. They are NOT digitally edited, modified or altered to give you a fake appearance……..and fool you. We take great pride in our work, our products and our services, and have lived up to that status since inception back in 1987. We invite you to click here to download our Roofing Brochure.

Our goal is to turn every empty rooftop decks into usable spaces...............and yes, we have approval letters from almost every roofing membrane manufacturer approving our products over there system.

.jpg)

Our architectural and ballast pavers are made from 100% recycled tires and rubber, a requirement by many architects, designers, engineers, municipalities, building owners and property managers who are looking to “go green” by helping earn SS credits and achieve LEED points. When seeking form and function as well as visual appeal, our unique rooftop paver products come in a wide variety of colors and thicknesses to complement any office, deck, patio, plaza, rooftop, apartment, hotel or buildings sustainable green roof and/or terrace by offering you the ability to increase your usable square footage while extending the life of your waterproofing membrane.

Our products are engineered and manufactured using the best and safest materials available through our sister company which recycles tires and rubber in-house, that is how you will know it is the right solution for you. We have developed and patented a superior, resilient product made from environmentally friendly recycled (pre and post-consumer waste) tires and rubber that is clean and safe to use in almost any environment. Our ingenious self-interlocking design with the new “Button-Lock™ Technology” coupled with our unique “Drain-Port System” gives us an unparalleled advantage over competing products in the industry.

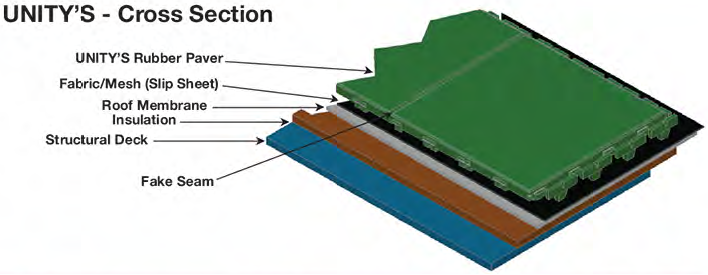

Unity has created an impressive way to turn unsightly rooftops into usable spaces that are appealing, while at the same time providing thermal and mechanical protection. Our system will benefit you and the environment by reducing building energy consumption, extending the life of your waterproofing membrane, reduce storm water runoff AND increase the resale value of your property. The performance, long term value, color diversity and economical benefit of our products has appealed to architects, engineers, designers building owners and managers when renovation and/or retrofit such rooftop projects that plays an integral part in promoting healthier and cleaner environment by “going green”.

The sheer size, weight, durability, self-interlocking design (with “Button-Lock™” Technology), built-in pedestal system, coupled with our specially formulated one-part adhesives (for gluing the self-interlocking joints) provides resistance against premature product-to-product separation, curling and pealing, wear-and-tear, leg fatigue and most importantly.........wind up-lift. Our system will conform to almost any low-sloped waterproofing membrane system – old or new, while at the same time, provide noise reduction, superior drainage and easy access for any maintenance issues.

Thank you for the rubber pavers you and your company supplied and installed on our rooftop patio. The over-

whelming compliments we are receiving is amazing. It’s like adding a back-yard space that we never had

before. WOW. Every building that has tenant access, or any access for that matter, should purchase your

wonderful products. Keep up the good work.

- Mr. Poloski, Owner/Manager

Space is the most valuable asset in most major cities. There is an increasing demand for our products to be installed on rooftops and indoors. We are the only manufacturer to pass several types of a Class “A” Fire and Wind Up-lift tests, including modified versions for roof coverings, making our products superior for such installations. If required, a fire rated version is available prior to ordering.

Technical Information:

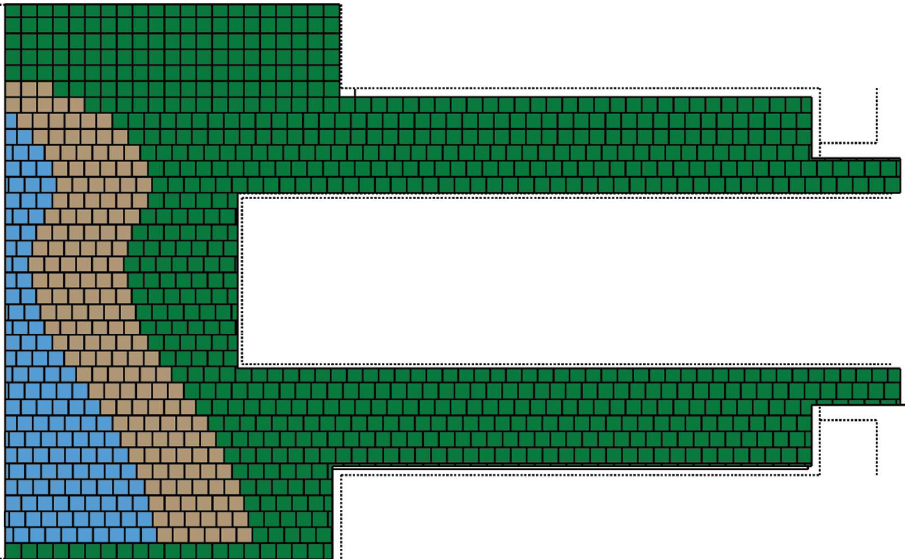

Top View:

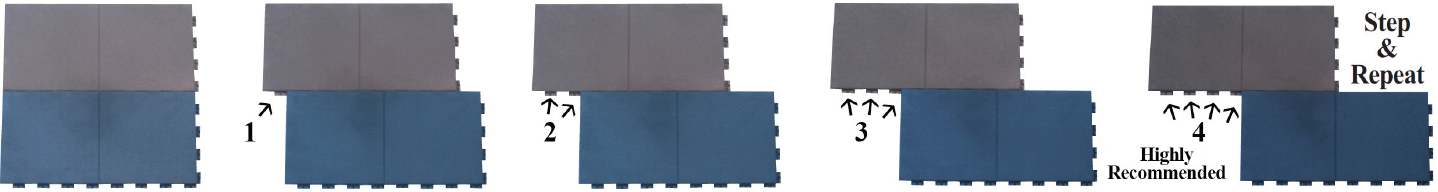

What sets our products at a level that others can only marvel at is our authentic, double, tile/mat/block/paver system that is almost 100% larger in size then most other products on the market. Our flexible rubber paver system has a fake seam down the middle is designed to accommodate and adjust to, minor low-sloped variations in a roof membrane. The resilient double panel allows us to have a monolithic Step & Repeat pattern, which lines real seams with fake seams as if you were installing "brickwork". These technological developments in design acts as a backup to further resist separation, curing, peeling and wind up-lift across any roof assembly. The bottom line is..........fake seams force real seams to stay in place.

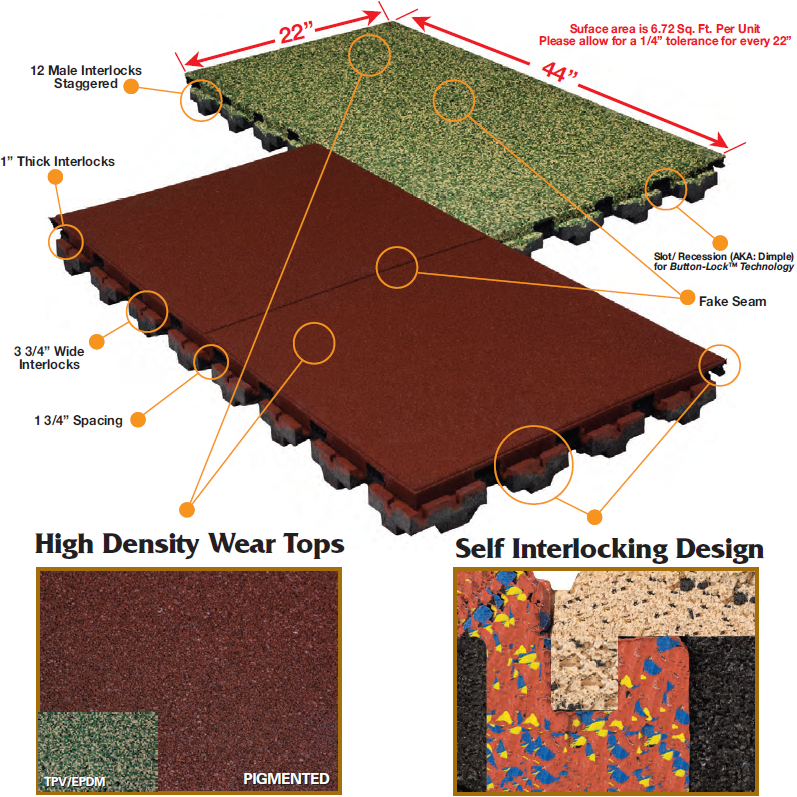

| Our High Density Wear-Top is manufactured using recycled rubber in conjunction with a wide variety of slip resistant Pigments and/or blended EPDM/TPV material, coupled with our specially formulated binders. These high density, textured wear-top options are resilient and won't crack, puncture or heave in the most hostile of weather conditions. This versatility is unmatched and provides year round use to the end-user. |

The patented C-shaped self-interlocking design is built directly into the product itself, It locks tightly together thanks to the supporting "back-wall", which prohibits unnecessary separation, curling, pealing, shifting and wind up-lift. It is installed with our specially formulated glue/adhesive, while still providing unlimited access to sub-base materials for any maintenance related issues. |

Size does matter in this case as it allows installers to install almost twice the square footage per man hour then the conventional square tiles, a savings that is unmatched in the industry today.

Furthermore, our patented, quadruple, self-interlocking design that is 40% larger in size with 60% more area to glue/adhere, eliminates the need for accessory items such as:fasteners, pins, clips, blocks, grids, etc., to hold the product together. This new technological advancement in design further strengthens the Pull Force of our products, both horizontally AND vertically, as it is locked into place in all directions, which in turn will truly provide the strongest locking mechanism along various parts of our products. In turn, prohibiting them from exposing itself to vertical up-lift and flight characteristics when installed on rooftops, a common design flaw found in a standard square tiles/mats/blocks/pavers on the market today. A characteristic that can only be found here.

|

Our twelve staggered interlocking joints:

- Lock tightly together thanks to the new “Button-Lock™” Technology.................no movement when interlocked together.

- Provide faster and easier drainage, allowing no foreign objects to harbor between the interlocks which are commonly found in competing products on the market today.

- Helps prevent our products from shifting away from one another - a necessity in active, “common” areas.

- Eliminates future problems such as expansion and contraction which may encourage wind up-lift.

- Allow owners of our products to unlock the tabs in order to remove a damaged product, repair a substrate/roof, or relocate a surfacing/flooring area if necessary.

- When loose laid pavers are interlocked over the roofing membrane, it offers superior protection without limiting the accessibility to the membrane. This versatility is unmatched and decreases the repair expenses to the consumer allowing, for many years of hassle-free use and enjoyment.

|

|

|

Unlike other products on the market that require glue to be applied after it is installed (which only provides a butt-to-butt adhesion), Unity’s products allow for glue to be applied during the installation process. This revolutionary technology allows glue to be applied inside the self-interlocking joint and on top for a free-flowing adhesion throughout the self-interlocking system, including the back wall as seen here, providing FIVE layers of protection.

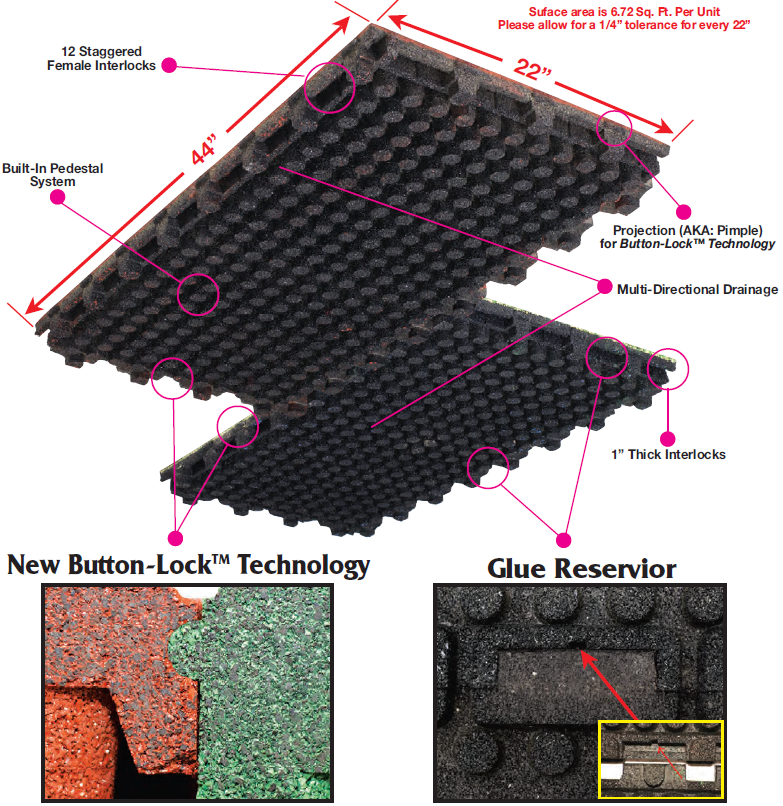

Bottom View:

With this view from the bottom, one can see that our solid coned (feet and/or leg) bottom design acts as a shock absorber from falls onto the surfacing below. It is also designed to help with storm water management by allowing water to flow freely in multiple directions to the drainage outlet when installed on a solid sub-base material, such as concrete (cement), asphalt (blacktop) or even rooftops. Our unique bottom-design also eliminates any “hard spots” and/or “picture framing,” a common design problem with other competing products on the market today.

|

A revolutionary advancement in design is out patented "Button-Lock" technology where the projection of one tile is receivable by the corresponding slot/recession of another tile. It is designed to literally "snap & hook" into place, which provides an extra layer of protection to the end user. This additional locking mechanism provides the most secure installations on the market, both horizontally and vertically.

|

This advanced design feature, found on the inside wall of our female interlocks, allows for any access glue to ooze down and away from the top of our products during the installation process thanks to the built-in channeling system seen here. This continual advancement in design assures architects, engineers, designers, consultants, owners, end-users and contractors a qualified, professional installation that is fixed and functional throughout the life of the product.

|

We invite you to click here to proceed to our "video page" to truly see how all of our feature and benefits mentioned above really work

Handicapped Accessibility:

A rooftop, walkway pad or any surfacing, flooring and paver area that has uncontrolled access should require a unitary surface (i.e. rubber tiles/mats/blocks and/or pavers) to ensure the highest standard of safety for people of all ages. A unitary surface, such as ours, also reduces high maintenance costs of roof membranes that are commonly associated with the lack of any type of material.

More and more agencies are becoming aware of the fact that all public facilities must be handicapped accessible. With the 1991 passage of the “Americans with Disabilities Act” (ADA), many areas are being planned or modified to give people with disabilities an opportunity to participate in everyday activities. Regardless of your needs, it is not easy to have the mobility to maneuver strollers, crutches, wheel chairs, canes, walkers, etc, through many types of roofing products. All of Unity’s products are designed to give children and adults with or without disabilities and varying mobility access to freely navigate as per ASTM’s: Accessibility-Rotational Penetrometer test.

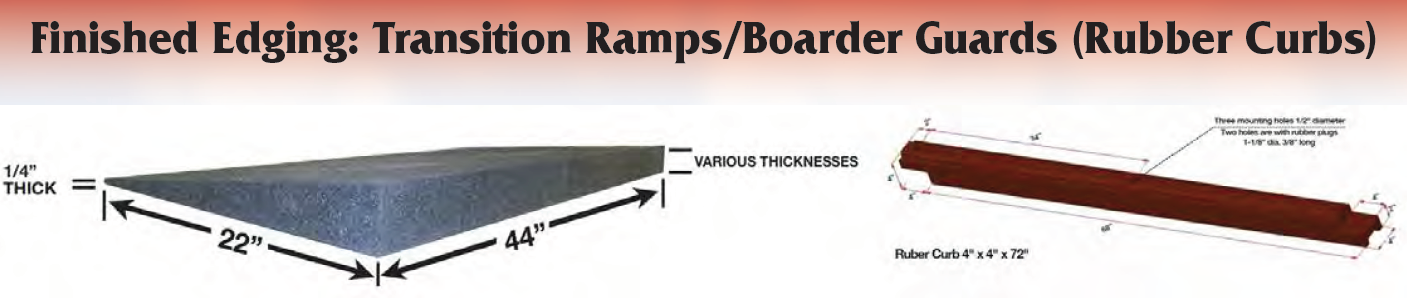

Transition Ramp/Edging:

|

|

|

When a wall, fence, curb, parapet or other boarding systems is not available, our complete line of transitional ramps provides everything you need to achieve the professional solution you are looking for to compliment any area, giving it a complete “finished” look. These transitional ramps are designed to work together, providing easy access to and from our unitary rubberized safety surfacing, flooring and paver products. They also come in a wide variety of colors and thicknesses to fit your indoor and outdoor needs.

|

We also offer “Rubber-Curbs” that can be used as finished factory edges. Click throughout our website to learn more.

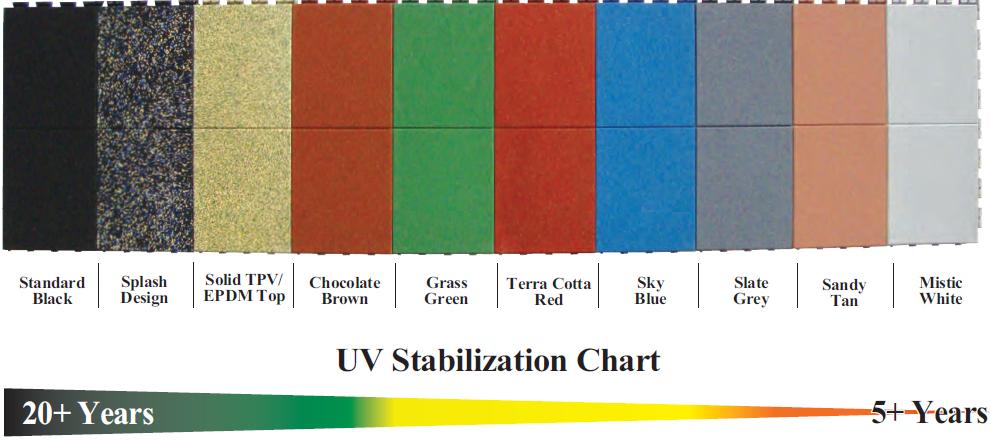

Standard Color Choices (Pigmented & EPDM Chips):

All of Unity’s products are made with clean tire buffing and/or crumb rubber granules recycled in-house and mixed with a clear urethane. Colorized products are made with pigmented dyes combined with black recycled rubber that do not release harmful VOC’s, and are produced free of zinc, latex, lead, phthalates and heavy metals. These pigments are dispersed throughout the top of our products for consistency at an economical price. A wide variety of colors to choose from include: black, splash, silver, red, green, tan, blue, white, teal, brown, purple, and TPV/EPDM TOP.

Click here to proceed to our "Design With Pigments Page" to learn how you can create beautiful designs on your next project.

EPDM/TPV Blending:

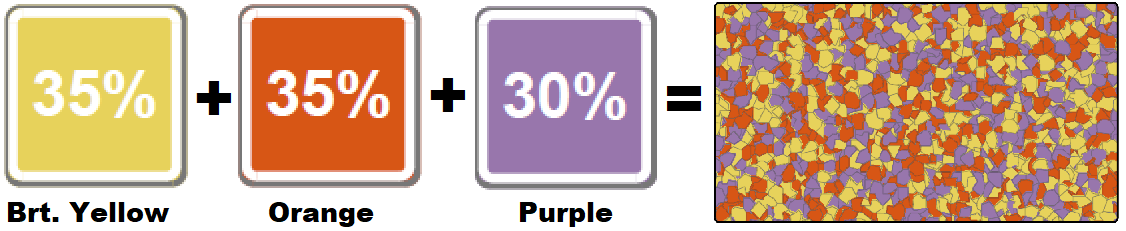

With limitless imagination, our Splash Design (left side) and solid TPV/EPDM top (right side) tiles/mats/blocks/pavers can be manufactured using diverse color combinations and/or percentages generated from a plethora of TPV/EPDM granules listed below. This superior alternative can have unlimited design potential that would compliment any area allowing architects and designers to express design through creativity in blending. Manufactured to spec, the TPV/EPDM chips exhibit superior UV and abrasion resistance that will last a lifetime. The TPV/EPDM choices include:

Blending Examples:

Project Examples:

Produced with Aromatic Binder only. To avoid temporary yellowing/ambering/oxidizing from UV Rays during/after installation, it is important to upgrade to Aliphatic Binder prior to ordering, at an additional cost.

Click here to proceed to our "Design With TPV/EPDM Page" to learn how you can create beautiful designs on your next project.

Installation Info:

|

|

|

Our products place in the intermediate category regarding installation difficulty. Contractors carry out most of the installations. An installation manual/ guide is available upon request (and is shipped with every order). Adhesive must be applied to the solid sub-base and self-interlocks of our products, both inside the joint and on top. Bolts may be applied to the male interlocks and countersunk for added strength and security (on solid sub-bases only, except for rooftops). Tools that are common for most installations include: an extension cord for electric use, a utility knife and/or jig saw for cutting, a straight edge to make your cuts accurate, a string line and tape measure. A trowel and/or caulking gun may be needed for gluing purposes as well as a drill for bolt-down applications. As with any construction site, it is always important to have a cleaning compound and medical kit on standby just-in-case.

|

Installation Layout Options:

We now offer a “running bond” method of installation that can stagger the joints anywhere along the horizontal self-interlocking tabs. A “running bond” can help with slight variations during installation, while at the same time allowing for increased diversity in custom designs, layouts and patterns to express free flowing lines similar to “pour-in-place (PIP) that will expand the minds of many and “WOW” the end-users.

Free Flowing Design Options:

Free flowing designs you’ve been dreaming of in a traditional paver system can now become a reality with the use of our products. With this newly patented “running bond” method of installation, one can create as many bold themes, layouts, patterns and designs throughout an area as one can image. Architects and designers alike can express unlimited imagination and complete design freedom for any vision regardless of size, style and/or complexity, by locking our products along ANY self-interlocking tab. This unique method of installation is unmatched in the industry today.

Our products can be cut on site to conform to the most difficult of shapes, patterns, designs and layouts. This gives your area a nice clean “finished” look for everyone to enjoy, as seen in the photographs below:

Click here to proceed to our "Design With Layouts Page" to learn how you can create beautiful designs, layouts and patterns on your next project.

Sub-Base Options:

|

|

Since the life expectancy of our products far exceeds any other surfacing, flooring and/or paver product on the market today. To maintain such superiority, we suggest installing an approved waterproof membrane down, with a slight pitch for drainage. Other types of surfacing options include concrete (cement) asphalt (blacktop), crushed stone, quarry, wood decking and/or any standard indoor/outdoor flooring that do not have stress cracks. It is important to consult with your local codes prior to selecting a sub-base material.

|

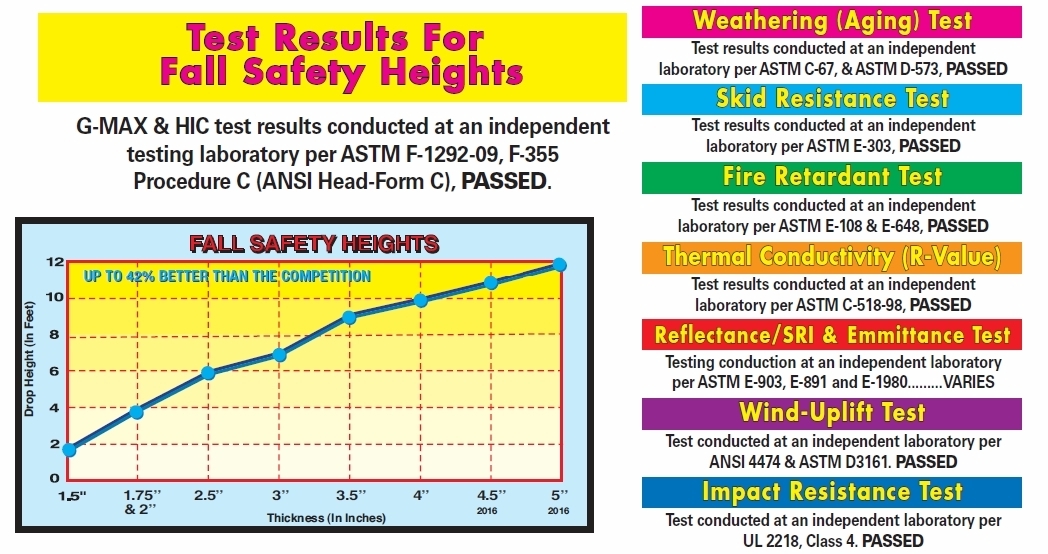

Test Results:

|

|

The core function of our product testing is to provide peace-of-mind after it is installed. With the help of independent testing laboratories, we ensure that our products meets or exceeds these ASTM, CPSC, ADA, FM standards by up to 42% when compared with other competing products on the market today. These critical tests are the value of avoiding legal problems resulting from lawsuits that stem from inappropriate roofing materials/accessories. Additionally, we go above and beyond, by internally testing our products for any quality control issues that may hinder the test performance rating before it leaves our factory floor and after it is installed for several years. It is important that peace-of-mind is carried over from rooftop to rooftop, year after year.

|

Don't let fire and wind have its way. Put a lock on your investment with Unity pavers that withstands wind speeds of more that 150 mph AND meets or exceeds Class "A" fire testing for rooftop applications...........something that can only be found with the Unity brand of products and services.

If you would like to see the actual test results, please click here.

Warranty:

Due to the extreme durability of our rubber paver system, each and every product manufactured by Unity is backed by a full warranty to protect you and your investment from manufacturing defects. New “extended” warranties have been added to further strengthen the guarantee of our products and services. It is specifically designed to assist architects, engineers, municipalities and project managers to maximize the cost and performance warranty benefits associated with our system. In the end, we offer our customers exceptional value that is unmatched in the industry today. Contact Unity directly for more information. A written warranty is available upon request.

Click here to download our roofing brochure for your review and consideration on your next project. If you would like, you can also scan our QR code below to immediately store our contract information in your smart-phone.

|

|

We believe that our products size, weight, durability, longevity, fall protection ratings (the highest in the industry), and ability to have an integrated - self-interlocking system featuring the new “Button-Lock™” Technology (for rooftop applications), with bolt-down capabilities (for playground use), can be effectively and easily secured on site to eliminate the potential for product-to-product separation, curling, peeling, wind-up-lift, vandalism and maintenance.

Everyone at Unity would like to encourage you to close the loop with the use of our products made from recycled materials. And for that, thank you for your interest in our products and services. We invite you to continue scrolling through our website for additional product information, or take a picture of this QR code with your smart-phone.

|