unblocked games

unblocked games

unblocked games

USGBC-LEED

USGBC (United States Green Build Council

LEED (Leadership in Engineering and Environmental Design)

|

Made from environmentally friendly recycled rubber (both pre and post consumer waste), our in-house recycling facility and patented manufacturing process to produce finished products play an important role in promoting a cleaner and healthier world by re-using this waste that once went into landfills. The end result allows for a cleaner and healthier place to live…….world-wide.

PS: Our finished products can be re-recycled again into the same or a different product as well, known as EcoCyclable.

|

USGBC-LEED (Leadership in Energy & Environmental Design):

The U.S. Green Building Council is the nation's foremost coalition of leaders from across the building industry working to promote buildings that are environmentally responsible, profitable and healthy places to live and work. It is leading a national consensus for producing a new generation of buildings that deliver high performance inside and out. As a member of USGBC, using our products may help to achieve LEED points/credits (up to 7).

The LEED program focuses exclusively on an individual building structure not a specific product. The purpose of the program is to evaluate the whole building from an environmental performance perspective over the buildings life cycle to determine if the building is a "green" building.

Sustainability:

Under normal types of foot traffic, rubber flooring typically outperform most other competing products on the market today. Our system can be installed in such a way that their life span is doubled, if properly maintained. We can achieve this by either moving our safety surfacing, flooring and paver products away from high traffic zones and exchanging them with other self-interlocking tiles/mats/blocks/pavers in low traffic zones, or provide our "dual-density" version. In addition, our self-interlocking tiles/mats/blocks/pavers are sometimes reversible (depending on the product) and easy to re-install if needed, which truly extends the life span. It is the benchmark by which all others are measured.

|

|

|

Once our unitary rubberized safety surfacing, flooring and paver products are no longer being used, they can be shipped back to “UNITY” for re-recycling. The resulting materials will then be re-used in the manufacturing of all of our other environmentally friendly products and services we produce, such as, but not limited to: Tough-Land, Pave-Land, Play-Land, Soft-land, XL-Series, Rubber-Curbs, Wear-Pads, Rubber Mulch and OEM products.

Key Differences Between: LEED-NC, LEED-CI and LEED-EB:

In November 2004, the USGBC released two additional rating systems: LEED_CI and LEED-EB to accompany LEED-NC. All three programs are part of a comprehensive suite of LEED green building rating tools the USGBC has developed to promote green design, construction and operations practices in buildings nationwide.

LEED for Commercial Interiors (LEED-CI) addresses the specifics of tenant spaces in offices, retail and institutional buildings.

LEED for Existing Buildings (LEED-EB) addresses the sustainable operation of existing buildings, and covers building operations and systems upgrades in existing buildings where the majority of interior or exterior surfaces remain unchanged.

LEED Contribution:

LEED is a self-assessing rating system based on a point system that focuses on a number of individual building structure, design and construction categories, not a specific product, which will reduce a building's environmental footprint. Unity can help with four of the categories:

- Recycled Content (very high)

- Local / Regional Materials

- Construction Waste Management

- Low-Emitting Materials

The purpose of the program is to evaluate the whole building from an environmental performance life cycle perspective and to determine if the building is "green", or "going-green", We can help with two of the categories -

- Materials and Resources

- Indoor Environmental Quality.

The following chart summarizes the point potential for both these categories and shows where Unity's rubberized safety surfacing, flooring and paver products may help you contribute to the potential earning of credit points.

|

Project

|

Category

|

Credits

|

# of points available

|

|

Materials & Resources

|

Recycled Content

|

MR 4.1

|

1

|

|

|

Recycled Content

|

MR 4.2

|

1

|

|

|

Local/Regional Materials

|

MR 5.1

|

1

|

|

|

Local/Regional Materials

|

MR 5.2

|

1

|

|

|

Construction Waste Mgt

|

MR 2.1

|

1

|

|

|

Construction Waste Mgt

|

MR 2.2

|

1

|

|

Indoor Environment quality

|

Low Emitting Materials

|

EQ 4.1

|

1

|

In some projects, using only our products has provided enough value to earn the recycled content and storm-water design credits. Contact us for more details.

Materials & Resources Credit 4: Recycled Content:

Intent:

Increase demand for building products that incorporates recycled content materials, therefore reducing the impacts resulting from extraction and process of new virgin materials.

Credit 4.1 (1 point) Requirements:

Used materials with recycled content such that the sum of post-consumer recycled content plus one-half (the value of) the post-industrial content constitutes at least 10% of the total value of the materials in the project.

The value of the recycled content portion of a material or furnishing shall be determined by dividing the weight of recycled content in the item by the total weight of all materials in the item, then multiplying the resulting percentages by the total value of the item.

Credit 4.2 (1 point in addition to MR.4.1) Requirements:

Used materials with recycled content such that the sum of post-consumer recycled content plus one-half of the post-industrial content constitutes at least 20% of the total value of the materials in the project.

Potential Technologies & Strategies:

Establish a project goal for the recycled content materials and identify material suppliers that can achieve this goal. During construction, ensure that the specified recycled content materials are installed and quantify the total percentage of recycled content materials installed. Consider a range of environmental, economic and performance attributes when selecting products and materials within the Unity line…..especially ones that are manufactured in the United States.

Unity’s contribution:

Our products are compressed of shredded tires and rubber known as SBR (100% post-consumer waste) that is cleaned (free of any metal’s and/or fiber’s) and colorful EPDM flex (30% pre-consumer waste). Recycled content is defined in accordance with the International Organization for Standardization document, ISO 14021 – Environmental labels and declarations:

1.) Post-consumer material – waste materials diverted from waste stream after consumer or commercial use.

2.) Pre-consumer material – materials diverted from waste stream during manufacturing process. Excluding is regrind, rework or scrap.

Based on LEEDS NC 2.1:

|

Unity's Products

|

Total Recycled

|

Post-Consumer Content

|

Post-Industrial Content

|

|

100% Recycled black

|

95%

|

95%

|

Varies (based on end user)

|

|

Splash Design

|

90%

|

90%

|

5%

|

|

Pigmented Colored

|

85%

|

85%

|

10%-15%

|

|

Rainbow-Land

|

100%

|

|

100%

|

|

TPV or Turf-Top

|

85%

|

85%

|

5%

|

~2.0 passenger car tires and/or SBR provide enough recycled crumb rubber for 1 tile/mat/block that is 1" thick.

~2.5 passenger car tires and/or SBR provide enough recycled crumb rubber for 1 tile/mat/block that is 1.75" thick.

~3.0 passenger car tire and/or SBR provide enough recycled crumb rubber for 1 tile/mat/block that is 2.0" thick.

~3.5 passenger car tire and/or SBR provide enough recycled crumb rubber for 1 tile/mat/block that is 2.5" thick.

~4.0 passenger car tire and/or SBR provide enough recycled crumb rubber for 1 tile/mat/block that is 3.0" thick.

~4.5 passenger car tire and/or SBR provides enough recycled crumb rubber for 1 tile/mat/block that is 3.5" thick

~5.0 passenger car tire and/or SBR provides enough recycled crumb rubber for 1 tile/mat/block that is 4.0" thick

Materials & Resources Credit 5: Local / Regional Materials

Intent:

Increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the regional economy and reducing impacts resulting from transportation.

Credit 5.1 (1 point) Requirements:

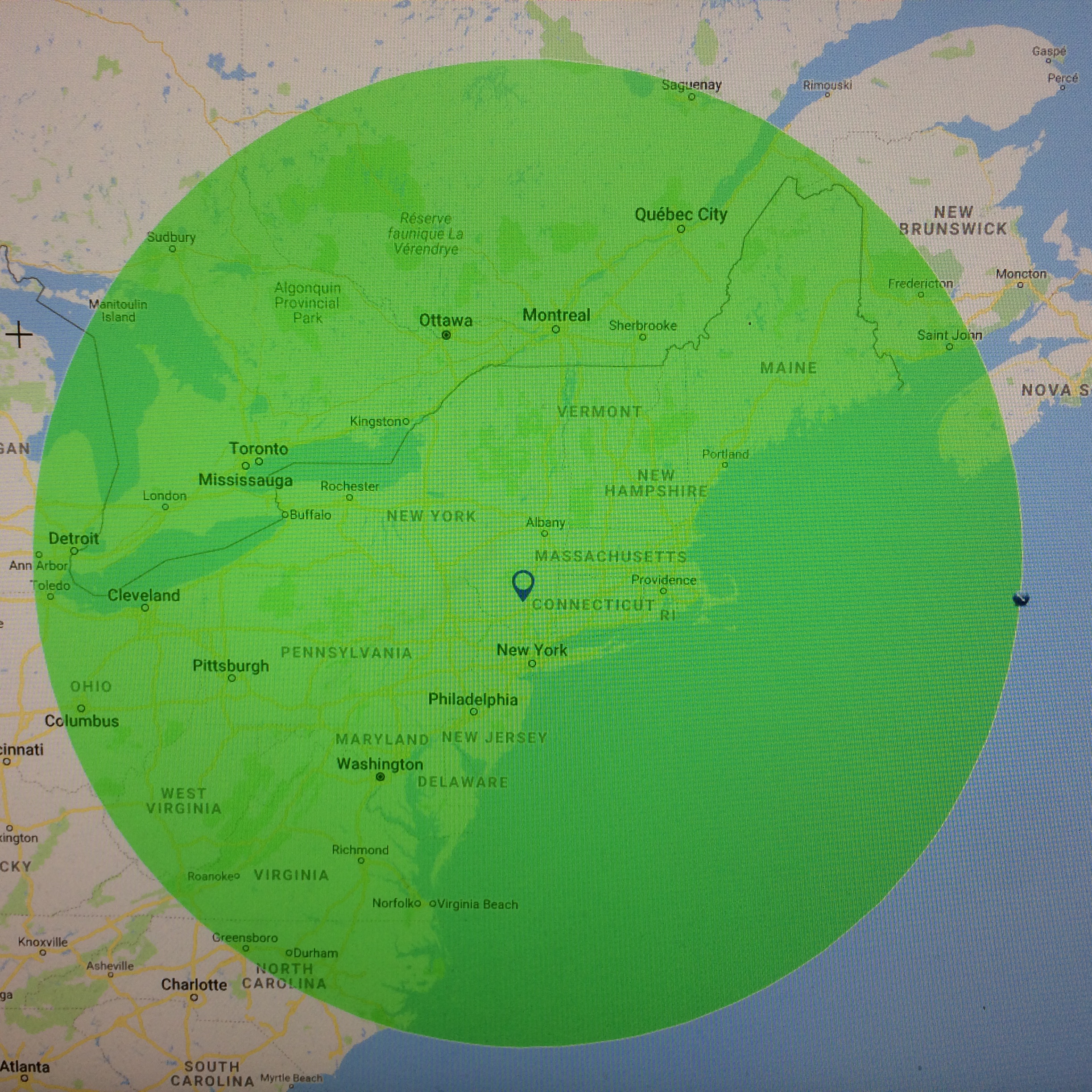

Use a minimum of 10-20% of building materials and/or products that have been extracted, harvested or recovered, as well as, manufactured within a radius of 500 miles of the project site. If only a fraction of a product or material is extracted/harvested/recovered and manufactured locally, then only that percentage (by weight) shall contribute to the regional value.

Credit 5.2 (1 point in addition to MR 5.1) Requirements:

Of the manufactured materials documented for MR Credit 5.1, use a minimum of 20% building materials and products extracted, harvested, or recovered (as well as manufactured) within 500 miles of this project site.

Potential Technologies & Strategies:

Establish a project goal for locally sourced materials and identify materials and material suppliers that can achieve this goal. During construction, ensure that the specified recycled content materials are installed and quantify the total percentage of recycled content materials installed.

Unity’s contribution:

Unity Creations, LTD. / Unity Surfacing Systems unitary rubberized safety surfacing flooring and paver products are manufactured in Saugerties, NY. 12477, and in Southern California. Currently, we are seeking other manufacturing venues throughout the US. Contact Us for more details.

LEED - NC 2.1 Construction Waste Management:

Intent:

Increase demand for building materials and products to be re-recycled, thereby supporting and saving the environment and reducing impacts resulting from waste.

Credit 2.1 (1-point) Requirements:

Recycle and/or salvage at least 50% of non-hazardous construction and demolition debris. Develop and implement a construction waste management plan that, at a minimum, identifies the materials to be diverted from disposal and whether the materials will be sorted on-site or commingled. Calculations can be done by weight or volume but must be consistent throughout.

Credit 2.2 (1 point in addition to MR 2.1) Requirements:

Recycle and/or salvage an additional 25% beyond MR 2.1 (75% total) of non-hazardous construction and demolition debris.

Potential Technologies & Strategies:

Establish goals of diversion from disposal in landfills and incinerators and adapt a construction waste management plan to achieve these goals. Consider recycling cardboard, metal, brick, rubber, acoustical tile, concrete, plastic, clean wood, glass, gypsum wall board, carpet and insulation. Designate a specific area on the construction site for segregated or commingled collection of recyclable materials, and track recycling efforts through the construction process.

Unity’s contribution:

Unity can contribute in two ways. All salvages and overages can be packages and shipped back to us in an effort to “close the loop”. Typically, we either recycle this material, or cut them up for customer samples. We can also regrind the material to use again into our recycled products. This strategy is exclusive know to Unity by way of: “Ecocyclable™” program. Defined as any product being used more than once (i.e. reusable) as the same, or different product (but the same ingredients (recycled rubber) as before. We are the only manufacturing company in the United States to have such a prestigious symbol of success.

Indoor Environmental Quality Credit 4: Low-Emitting Materials

Intent:

Reduce the quantity of indoor air contaminants that are odorous, potentially irritation and/or harmful to the comfort and well being of installers and occupants.

Credit 4.1 (1-point) Requirements:

The VOC (Volatile Organic Compounds) content of adhesives and sealants used must be less than the current limits of South Coast Air Quality Management District (SCAQMD) Rule # 1168, and all sealants used as fillers must meet or exceed the requirements of the Bay Area Air Quality Management District Regulations 8, Rule 51.

Potential Technologies & Strategies:

Specify Low-VOC Materials in Construction documents. Ensure that VOC limits are clearly stated in each section where adhesives and sealants are addressed. Review product cut sheets, MSDS’s, signed attestations or other official literature from the manufacturer clearly identifying the emissions limits.

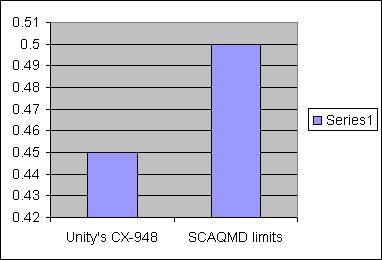

Unity’s contribution:

Adhesive/Glue

Unity’s CX-948 adhesive/glue is a single component polyurethane based tube (or trowel grade), structural adhesive. The patented formula is VOC compliant, and it contains no solvents or water. CX-948 provides excellent grab and outstanding bond strength formulated for use indoors and out. The VOC content is 45 grams per liter, which falls below the current SCAQMD (South Coast Air Quality Management District) VOC (Volatile Organic Compounds) limit of 50 grams per liter.

Storm Water Management Credit 6: Storm-water Rate and Quantity:

Intent:

Limit disruption and pollution of natural water flows by managing and/or eliminating storm-water runoff, increasing on-site infiltration and eliminating contaminants.

Credit 6.1 (1-point) Requirements:

Implement a storm-water management plan that decreases the volume of storm-water runoff from the one- or two-year 24-hour design storm, reduces impervious cover, promotes infiltration and captures and treats the storm-water runoff using acceptable best management practices.

If existing imperviousness is less than or equal to 50%, implement a storm-water management plan that prevents the post-development 1.5 year, 24 hour peak discharge rate from exceeding the pre-development 1.5 year, 24 hour peak discharge rate.

OR

If existing imperviousness is greater than 50%, implement a storm-water management plan that results in a 25% decrease in the rate and quantity of storm-water runoff.

Potential Technologies & Strategies:

Design the project site to maintain natural storm-water flows by promoting infiltration. Specify garden roofs and pervious paving to minimize impervious surfaces. Reuse storm-water volumes generated for non-potable uses such as landscape irrigation, toilet and urinal flushing and custodial uses.

Unity’s contribution:

Unity’s products are pervious, achieving .13 gallons per minute, per square foot of surface area via storm-water filtration at the body of the product and .21 gallons per minute, per square foot of surface area via storm-water filtration at the seam of the product. Additionally, Unity’s products can be combined with other storm-water management solution’s to meet this requirement…….including but not limited to “green roof” applications.

Heat Island Effect Credit 7: Non-Roof:

Intent:

Reduce heat islands (thermal gradient differences between developed and undeveloped areas) to minimize impact on microclimate and human and wildlife habitat.

Credit 7.1 (1-point) Requirements:

Provide shade (within 5 years) and/or use light-colored/high-albedo materials (reflectance of at least 0.3) and/or open grid pavement for at least 30% of the site’s non-roof impervious surfaces, including parking lots, walkways, plazas, etc.; OR place a minimum of 50% of parking spaces underground or covered by structured parking; OR use an open-grid pavement system (less than 50% impervious) for a minimum of 50% of the parking lot area.

Potential Technologies & Strategies:

Shade constructed surfaces on the site with landscape features and minimize the overall building footprint. Consider replacing constructed surfaces (i.e. roof, roads, sidewalks, etc.) with vegetated surfaces such as garden roofs and open grid paving or specify high-albedo materials to reduce the heat absorption.

Unity’s contribution:

Unity has developed a variety of compliant EPDM/TPV colors with an SRI of up to 86. We are also in the process of testing several other recycled materials to increase the SRI exposure within our product line. Please contact us for a list of colors that meet this requirement.

Heat Island Effect Credit 7: Non-Roof

Intent:

Reduce heat islands (thermal gradient differences between developed and undeveloped areas) to minimize impact on microclimate and human and wildlife habitat.

Credit 7.2 (1-point) Requirements:

Use ENERGY STAR® compliant (highly reflective) AND high emissivity roofing (emissivity of at least 0.9 when tested in accordance with ASTM 408) for a minimum of 75% of the roof surface; OR install a “green” (vegetated) roof for at least 50% of the roof area. Combinations of high albedo and vegetated roof can be used providing they collectively cover 75% of the roof area.

Potential Technologies & Strategies:

Visit the ENERGY STAR® Web site, www.energystar.gov, to look for compliant products.

Unity’s contribution:

Unity has developed a variety of compliant Pigmented and EPDM/TPV colors with an SRI of up to 86. We are also in the process of testing several other recycled materials to increase the SRI exposure within our product line. Please contact us for a list of colors that meet this requirement.

Summary:

Unity is committed to operating its manufacturing and recycling business in a manner that uses resources wisely and protects the quality of the environment as well as the health and safety of associates, family friends, community and end users of its products and services.

The ingredients used in the assembly of our finished products, such as: urethane binders, fire retardant chemicals, pigmented dyes, EPDM’s/TPV’s, are all manufactured and/or produced in the United States of America. In addition, we go above and beyond in quality by utilizing machines and machine parts that are manufactured in the United States of America, producing an overall product that can truly be considered “American Made” through and through. As a result of such unique sole source capabilities, Unity is truly a world-class industry leader setting the standard by which all others are measured.

Here is a small list of the Approvals, Sponsors, Affiliates &/or Memberships:

For complete and comprehensive LEED credit information, please visit: www.usgbc.org, or simply Contact Us directly.