deneme bonusu

Paint

Pigmented Protective Coatings/Paints:

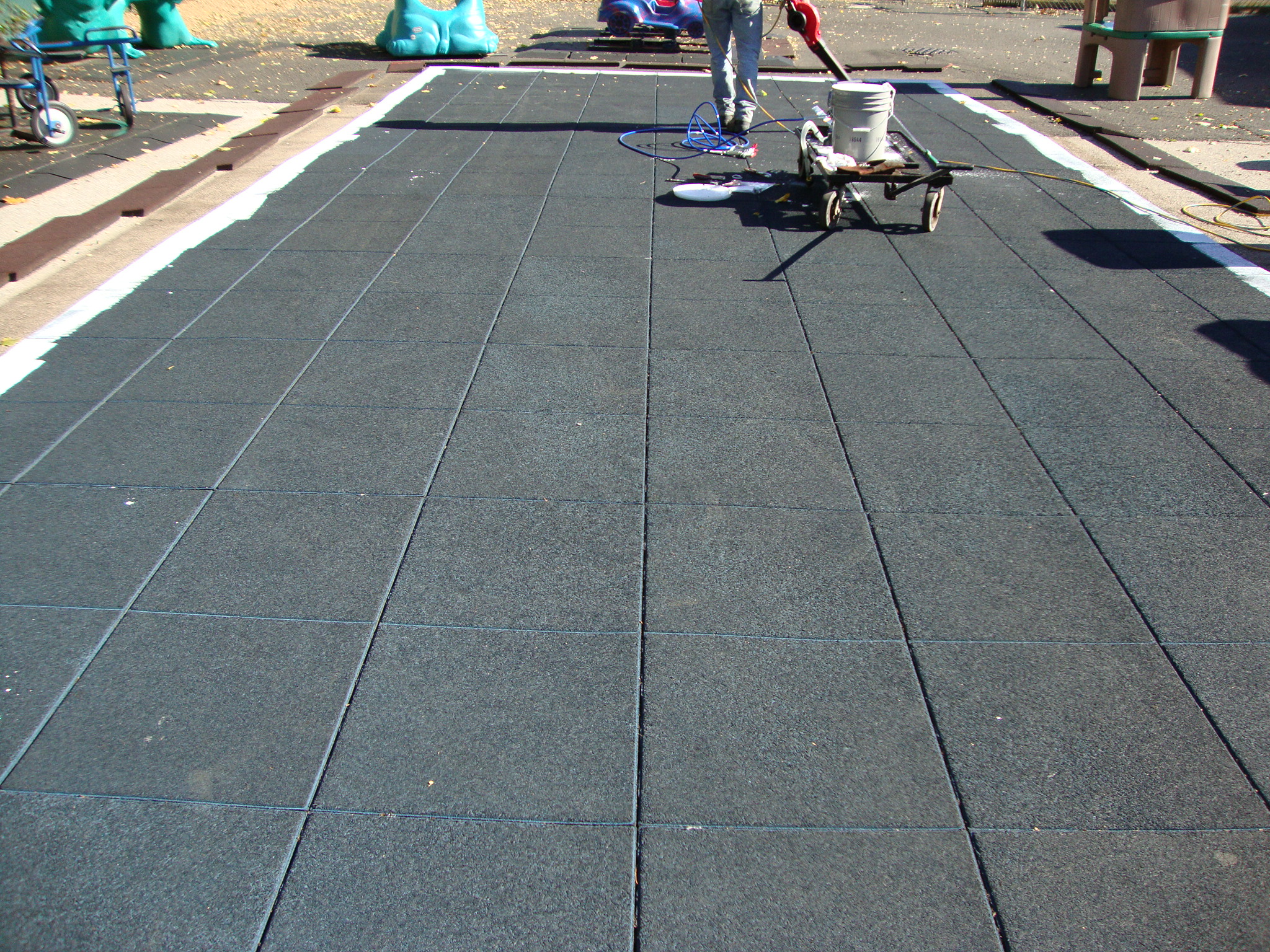

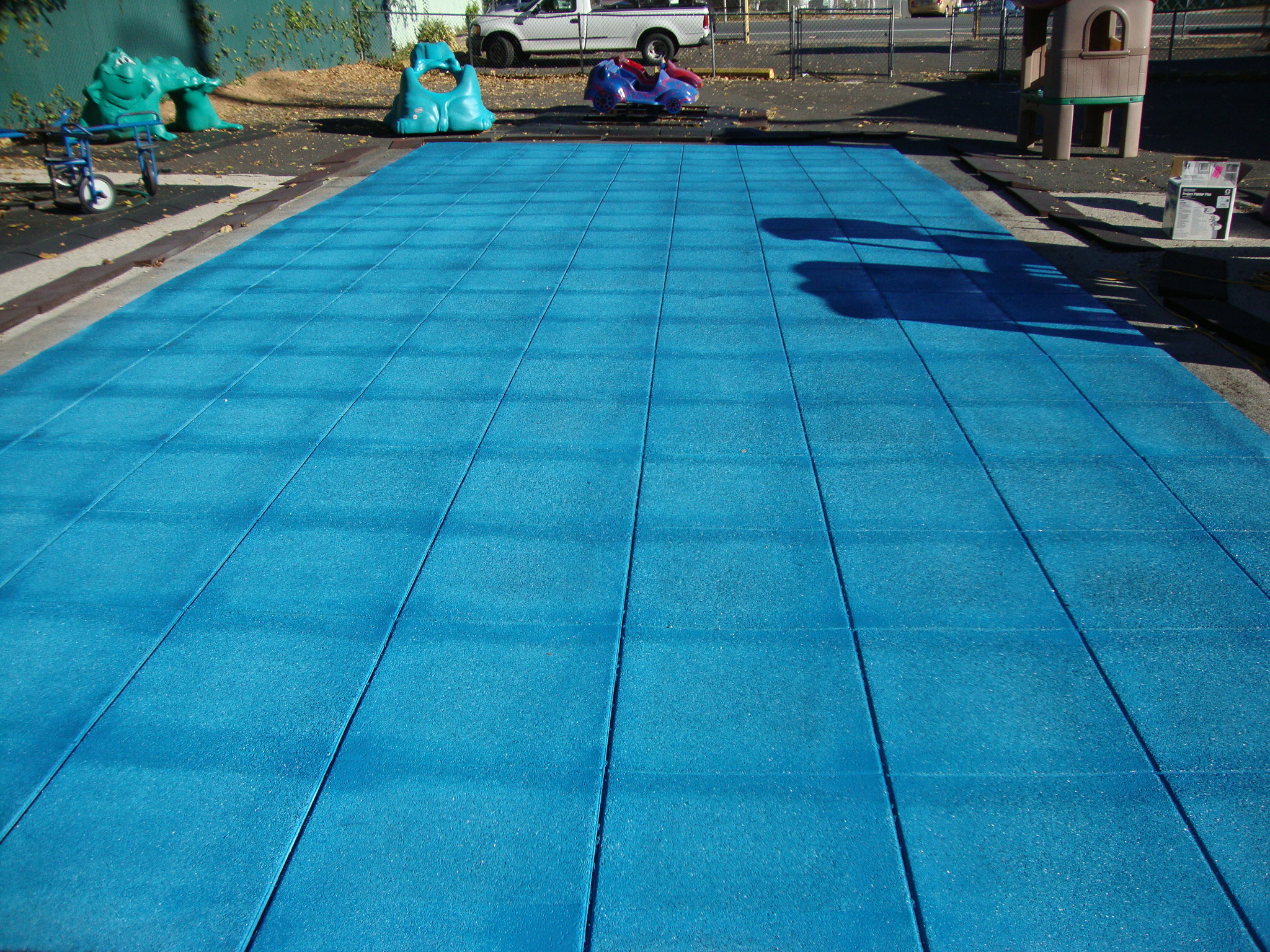

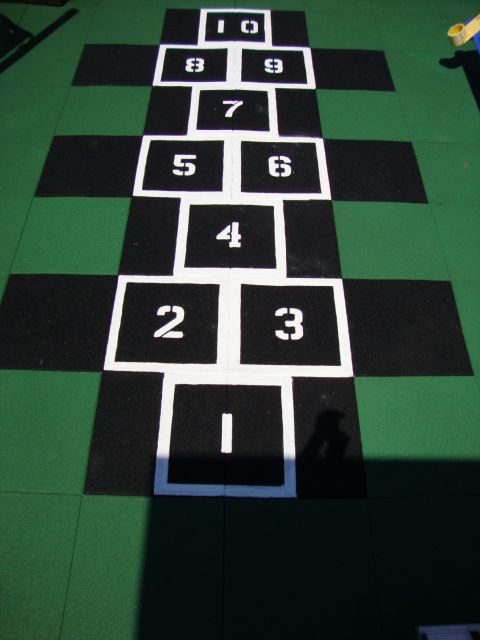

After many years of use, like any other products on the market today, Unity’s products can be painted for a fresh new look. We provide the necessary paints that can be sprayed on or simply rolled on for a brand new look. This application can provide less heat build up and extended life of our products for many more years to come.

| Before |

After |

|

|

The NEW N-1830 PAINT is a water-based, aliphatic, one-component, polyurethane coating that is designed for industrial molded-parts and play surfaces where UV-stability, chemical resistance, abrasion resistance and flexibility are required. This product is free of solvents and isocyanates and can be roller or spray applied.

OUTSTANDING FEATURES:

- Provides a long service life - Accommodates normal substrate movement and thermal stresses

- Withstands heavy use and environmental attack

- Maintains its attractive, clean appearance

- Easily scrubbed and cleaned

STANDARD COLORING OPTIONS (5-gallon pales only):

APPLICATION:

All surfaces to be coated must be clean, dry and completely free of oil, grease, dust, and any other substance that may interfere with adhesion. N-1830 may be applied by brush, roller or airless spray technique. Typically, it is applied at a rate of 50 square feet per gallon for the 1st coat and 150 square feet per gallon for the 2nd coat (sprayed); Yielding 100 sq. ft. (on average) for both coats being applied. Care must be taken to avoid creating foam or trapping air which may result in pinholes or hazing. Tools and equipment may be cleaned with xylene.

MAINTENANCE:

To repair damaged areas, pressure-wash clean and allow to dry overnight. N-1830 Paint may then be applied/reapplied to the clean, dry surface.

LIMITATIONS:

Store in a cool, dry place away from direct sunlight. Avoid opened containers as moisture will cure the material. Do not apply in temperatures below 40°F. Application must be protected from precipitation for at least 4 hours. Shelf life is twelve (12) months when stored in proprietary sealed containers between 45°F and 85°F.

PRECAUTIONS:

During handling of this product, it is recommended that standard safety equipment such as rubber gloves, chemical splash goggles and coveralls be worn. Avoid contact with skin and eyes. In case of contact, flush with clear water for 15 minutes. In case of eye contact, get immediate medical attention in addition to flushing. Do not ingest. In case of ingestion, do NOT induce vomiting, do seek immediate medical attention. Keep out of reach of children and pets. For more information, call our Technical Department.

|

SPECIFICATIONS

Coating Type:……………………………........ water-based, aliphatic, one-component, polyurethane coating

Application Type:……………………………………………….. Sprayed or Brushed/Rolled

Pot Life:……………………………………………. 4 hours @ 70°F (50% R.H.)

Shelf Life:…………………………………………... 12 months

Recommended Thickness:……………….. 4-10 mils dry film thickness

Coverage:……………………………………… 2 coats = 100 s. f. per (1st coat = 50 s.f. / 2nd coat = 150 s.f.)

Packaging:………………………………………….. 5 gallon pails only.

Color:……………………………………………….. A variety of standard colors (and custom colors available)

TECHNICAL DATA

Specific Gravity (ASTM D-891):…………………………………………. 1.17

Density (ASTM D-891):……………………………….................... 9.76 lbs/gal

Viscosity (ASTM D-4889):…………………………………… 9,000 cP

VOC-Content (calculated):…………………………………………. 0.20 g/L

Taber Abrasion (ASTM D-4060):…………………………………….. 65 mg

Mar Fee (ASTM D-5895):…………………...................180 deg. Bend @ 20°F ASTM C-711

Impact Resistance (4mm indent):………………… No cracking or loss of adhesion if properly prepped

Water Absorption:………………………………… Zero ASTM D570-77

Working Time:…………………………………….. 4 hours @ 70°F (50% R.H.)

Drying Time:………………………………………. 4 hours @ 70°F (50% R.H.)

Cure Time:………………………………………… 24 hours @ 70°F

Exterior Durability:………………………………. Good resistance to UV and harsh weather extremes

|

|

|

NOTICE: The information presented herein is based on tests and data that Unity believes to be reliable. It is intended for use by technically qualified personnel at their own discretion and risk. Since conditions of handling and use are beyond our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. Nothing herein is to be construed as a license to operate or a recommendation to infringe any patent.

Click here to down-load the PDF version for your files.