fake rolex

Fabric/Mesh

Geo-Textile Fabric/Landscaping Mesh:

|

|

Our top quality, non-woven filter fabric is a "slip-sheet" designed for compacted stone (loose filled) sub-base applications and rooftop membrane installations that our rubberized safety surfacing, flooring and paver products are found on. it is manufactured right here in the United States of America, as we see our customers as an extension of our family and want them to have only the best experience with all of our products and services. When fabric /mesh is need on rooftop application or over compacted stone sub-base installations, we feel it is our sole responsibility to provide the best possible product.

|

Its a cost conscience product used in light to medium duty stabilization and filtration applications designed to protect your sub-base materials below and our products above. This fabric/mesh is constructed of 100% Non-woven polypropylene for longer life spans, and is easy to cut and install with any blade or razor. It is available in 4’x300’ rolls, with the option to wider and longer.

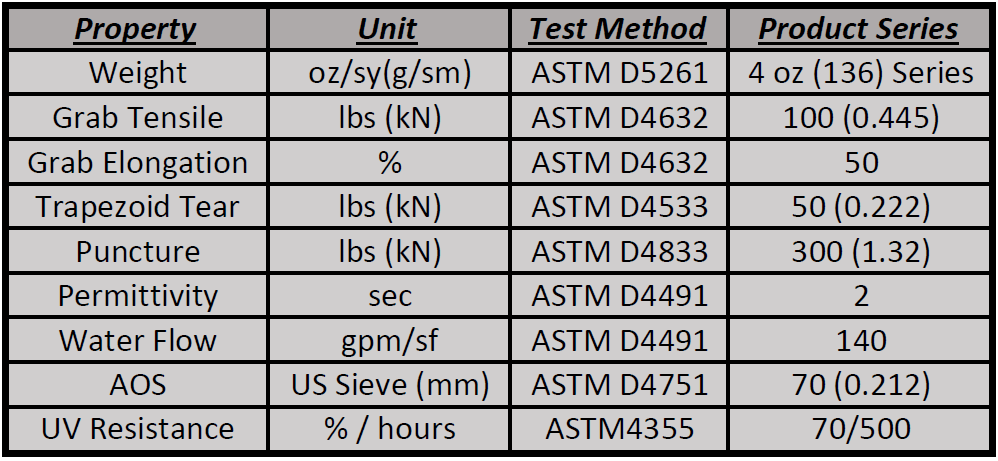

Technical Specifications:

Size:

4ft. X 300 ft. Rolls

Product Installation Procedure:

GROUND-LEVEL INSTALLATIONS:

- Dig out the area (6-8” deep, depending on the thickness of tile being installed) where you want the products installed.

- Tamp ground area level, ready for 1st layer of this fabric / mesh.

- Install your first layer of fabric / mesh overlapping the area by 3” (inches).

- Add the board system as required (see specification), usually concrete, asphalt, wood, plastic or rubber.

- Add recycled crushed stones, RCA, stone blend, item-4 &/or stone dust within the area. As an example: If you are installing our 2 ½” thick rubber tiles/mats/blocks/pavers, you want your compacted area to be 2 ½” (inches) below grade (grade being outside the area in question (walkway, curb, building, parapet, etc.) This will insure that the top of our rubber products will meet with the top of your finished bordering system so there is no tripping hazard on or off the newly installed safety surfacing, flooring and paver area. Again, the recessed installations is not required, but HIGHLY recommended.

- Compact area level using a vibration machine. MAKE SURE ALL WAVES, HILLS AND VALLIES ARE REMOVED. Sand, dust and/or a fine powder may be needed to fill such voids to give the area a LEVEL surface that is required.

- Once compaction is met, installer can roll out your second layer of fabric / mesh in the opposite direction, cut to fit accordingly with the said boarding system. Don’t forget to overlap the seams at least 6”, both horizontally and vertically.

- Slits are cut where fabric will go around playground posts and/or objects.

- Fabric is put in place and stapled to the side of your boarder….typically wood. Glue may be used to tack it in place as well.

This product is not needed on/over any solid sub-bases, such as, but not limited to: asphalt (blacktop), concrete (cement) or any other SOLID sub-flooring material ,both indoors and outdoors.

Unity’s tiles/mats/blocks/pavers must be installed in accordance with our specified installation guide/manual.

ROOFTOP INSTALLATIONS:

Most often (600 sq. ft. or more) the Fabric/Mesh is needed, and installed prior to our products being applied on top of rooftop membranes. The fabric/mesh is a matter of individual preference on smaller, residential applications, 600 sq. ft. or less, or approved as such by the architect, engineer, designer and/or owner in advance.

To install the Fabric/Mesh in this manner, follow these steps:

- Remove any foreign debris found on the roof membrane by sweeping or blowing the area clean.

- Make sure all debris is free in, and around, roof drains, pitch-pockets, etc.

- Apply the fabric/mesh by rolling out a single row, while at the same time; begin installing products. Follow all manufacturers instructions found in the general Installation Guide/Manual.

- Once two rows of product have been successfully installed, continue rolling out a second row of fabric/mesh overlapping the first row by 6” (inches) and continue to install our products as you go. This will insure that the fabric/mesh does not blow away, or create problems during the installation process.

Don’t forget to: Cut a hole where playground equipment posts or other objects, such as drains will go. It is always recommended to cut around all drains for easier access when maintenance is required.

Product Testing:

Click here it see a video on how the fabric/mesh is applied to a sub-base.

Seller makes no warranty; express or implied, concerning the product furnished here-under other than it shall be of the quality and specifications stated herein. Any implied warranty or fitness for a particular purpose is expressly excluded and to the extent that it is contrary to the foregoing sentence, any implied warranty of merchantability is expressly excluded. Any recommendations made by Seller concerning uses or applications of said product are believed to be reliable and Seller makes no warranty of results to obtain. This data sheet supersedes all previous data sheets for this style and is subject to change without notice.